|

Principle of Operation

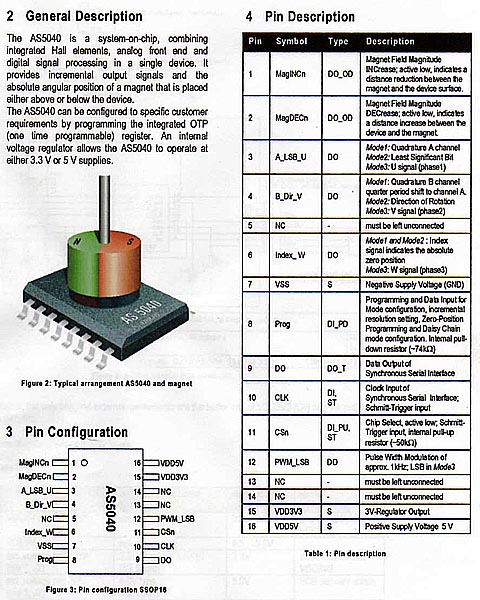

The AS5040 is a system-on-chip, combining integrated hall elements, analog front end and digital signal processing in a single device. It provides incremental output signals and the absolute angular position of a magnet that is placed above or below the device.

This device is manufactured by austriamicrosystems.

The full details can be found on their website at :-http://www.austriamicrosystems.com/

The AS5040 can be configured to specific customer requirements by programming the integrated OTP (one time programmable) register. An internal voltage regulator allows operating the AS5040 device at either 3.3 V or 5 V supplies.

The AS5040 chip consists of a ring of hall elements placed at

the center of the IC in a circle of 2.2mm diameter. The hall elements pick up

the field of a magnet placed above this hall array. This information is

digitized and fed into a digital signal processor which calculates the angle of

the magnet with a resolution of 0.35 degrees or 1024 positions per revolution at

a sampling rate of 10 kHz.

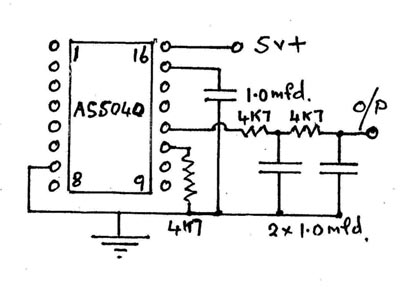

The digital angle information is available in several formats;

as a serial 10 bit data stream, as a pulse-width modulated (PWM) signal or as a

quadrature incremental signal.

Physical Details

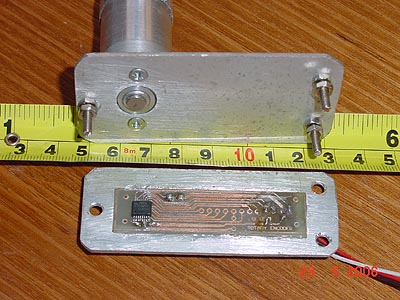

The chip itself is very small, measuring approx. 7.8 mm x

5 mm and has 16 pins and can be built up to replace the

potentiometers in many types of antenna rotators giving a far more

accurate and consistent readout than the original setup as there aren't

any mechanical contacts to wear. The only moving part is a

small rare-earth magnet 6 mm in diam. that needs to be attached to a shaft

and placed ~ 0.5 -5 mm above the AS5040. I recommend that you purchase the

correct magnet for this.

|